For construction projects in remote areas or high-standard infrastructure works (like highways and airports), logistics is the ultimate bottleneck. Sourcing high-quality sand and cubical aggregates often involves long haulage distances from stationary quarries, driving up costs and causing delays.

But what if you could bring the sand factory to the construction site?

The BENO XC-8500 Crawler Mobile VSI Crusher is the final, critical link in the modern mobile crushing chain. It transforms coarse aggregates into high-value Manufactured Sand (M-Sand) and perfectly shaped stones, right where you need them.

Most mobile crushing trains stop at the secondary stage (Cone or Impact crusher). While efficient, these machines sometimes leave the product with sharp edges or micro-cracks. The XC-8500 is designed for the tertiary stage:

· Aggregate Shaping: It rounds off the edges of 10-20mm stones, creating the tightly interlocking structure required for high-grade asphalt surfaces.

· Sand Making: It converts surplus 5-10mm chips into premium M-Sand (0-5mm), replacing expensive and scarce river sand.

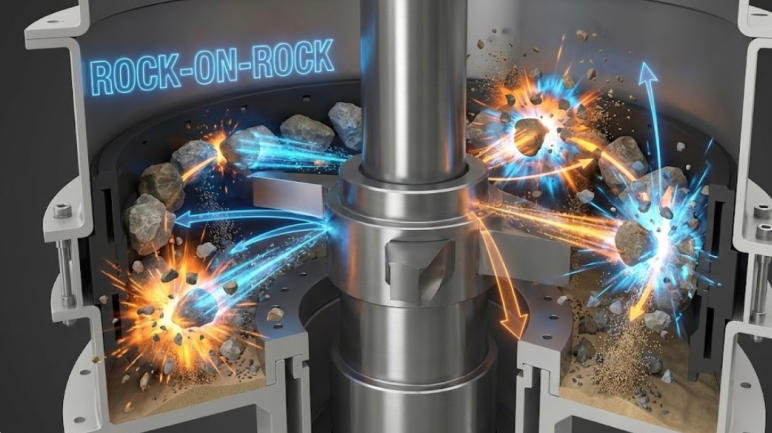

At the heart of this mobile giant is the high-performance BENO Vertical Shaft Impact crusher. Unlike traditional crushers that smash rock against steel, the XC-8500 utilizes the "Rock-on-Rock" principle.

· High-Velocity Impact: Material is accelerated by the rotor and thrown against a self-lined bed of rocks in the crushing chamber.

· Self-Destruction: The stones shatter along their natural cleavage planes.

The Result: This not only minimizes wear costs (since rock crushes rock) but also produces the most uniform, cubical particle shape possible.

The "XC-8500" isn't just a model number; it represents a commitment to high throughput.

· Heavy-Duty Tracked Chassis: Powered by a robust hydraulic travel system, the XC-8500 can climb gradients and navigate rough terrain to position itself directly next to your secondary cone crusher.

· Quick Setup: From trailer to production in under 45 minutes. No concrete pads, no electrical infrastructure required.

To maximize efficiency, the XC-8500 is designed to integrate seamlessly with other BENO mobile units. The Ultimate Layout:

· Primary: BENO Tracked Jaw (Crushes big rocks).

· Secondary: BENO Tracked Cone (Reduces size).

· Tertiary: BENO XC-8500 (Shapes and makes sand).

· Screening: Mobile Screen (Separates the final products).

This configuration gives you a fully autonomous, industrial-scale aggregate plant that moves as your project advances.

Low-quality crushed stone is a commodity; premium cubical sand is a high-margin product. With the BENO XC-8500, you stop being just a contractor and become a supplier of premium materials. Eliminate transport costs and control your own supply chain.