In the world of high-grade infrastructure construction, "crushed stone" is not enough. Projects like highways, high-speed railways, and airport runways demand premium aggregates, clean, and precisely graded.

For mobile contractors, achieving this quality usually meant hauling rock to a distant stationary plant. Not anymore.

The BENO Tracked Cone Crusher brings the precision of a stationary plant directly to your job site. It is the ultimate secondary crushing solution designed to work in perfect harmony with our Tracked Jaw Crusher, creating a mobile factory that delivers specification products from day one.

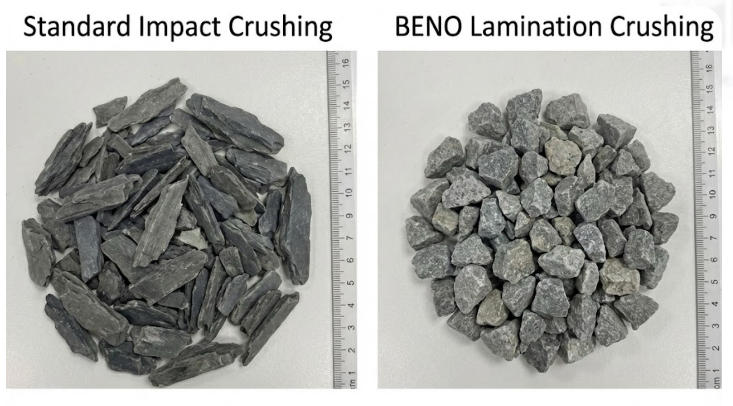

Why do BENO aggregates sell for a higher price? The secret lies inside the cone chamber. Unlike impact crushers that can create micro-cracks in hard rock, BENO utilizes the Lamination Crushing Principle (Rock-on-Rock).

Cubical Shape: Stones are crushed against each other, eliminating flaky edges and producing a highly cubical product that meets strict flakiness index standards (<10%).

High Strength: The finished aggregate retains its structural integrity, making it ideal for high-strength concrete (C60+) applications.

Profitability is calculated in cost per ton. Traditional hydraulic-drive mobile crushers are notorious fuel guzzlers. BENO changes the game with Hybrid E-Drive technology.

Mains Power: Plug directly into the grid or an external genset. The electric motor drives the cone crusher with superior efficiency, reducing energy costs by up to 30% compared to hydraulic drives.

Onboard Diesel: Working in remote locations? The onboard CAT® diesel generator ensures you are fully self-sufficient.

Mobile crushing shouldn't mean manual guesswork. Every BENO Tracked Cone Crusher is equipped with our Smart-CSS (Closed Side Setting) Automation.

Auto-Regulation: The system monitors engine load and chamber pressure in real-time. If the feed material changes (e.g., gets harder), the machine automatically adjusts the setting to maintain peak throughput without stalling.

Tramp Release: Detected a piece of excavator tooth? The hydraulic cylinders instantly release the pressure to let the metal pass, then automatically reset, protecting your investment from catastrophic damage.

A mobile cone crusher is only as good as its feed. The BENO Tracked Cone is engineered to accept the direct discharge from the BENO Tracked Jaw Crusher.

Synchronized Flow: When linked wirelessly, the cone crusher can signal the upstream jaw crusher to adjust feed rate based on hopper level, preventing spillage and ensuring a more consistent feed.

Don't compromise quality for mobility. With the BENO Tracked Cone Crusher, you get the best of both worlds: the ability to move instantly and the technology to produce high-value aggregates that pass the strictest lab tests.

Planning a Mobile Crushing Train?

See how the BENO Jaw + Cone combination can maximize your efficiency. Download the Case Study: High-Speed Railway Project or contact us for a custom configuration quote.