Global construction standards are tightening. With the depletion of natural river sand and strict environmental bans on dredging, the aggregate industry is undergoing a seismic shift toward Manufactured Sand (M-Sand).

But not all sand is created equal. For quarry owners and concrete batching plants, the challenge isn't just making sand—it's making quality sand that meets strict gradation and shape requirements.

This is where the Vertical Shaft Impact (VSI) Crusher acts as the definitive solution. Unlike compression crushers, the VSI is a master of shaping, transforming low-value stone chips into premium construction aggregates, making its investment value an important consideration when evaluating the vsi crusher price.

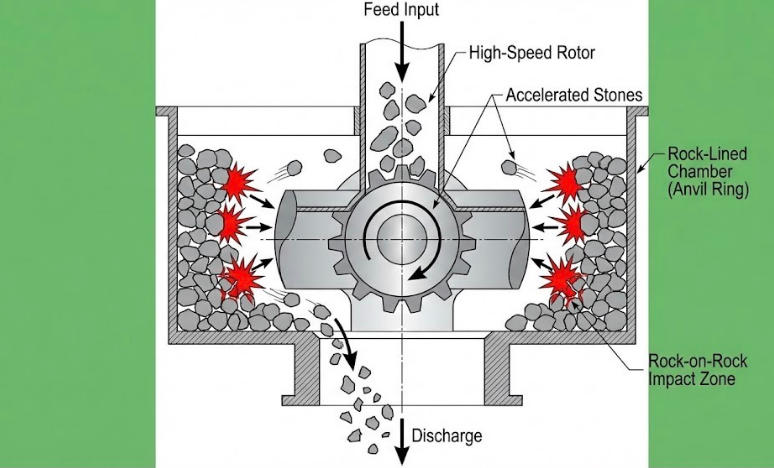

The brilliance of the VSI Crusher lies in its unique crushing principle: "Rock-on-Rock".

Instead of crushing stone against steel (which wears out steel rapidly), the VSI uses a high-speed rotor to throw rocks against a self-lined bed of other rocks within the crushing chamber.

1. Velocity Impact: Material falls into the center of the rotor and is accelerated to high speeds.

2. Collision: It impacts the material bed lining the outer chamber.

3. The Result: The stones shatter along their natural cleavage planes.

Why this matters for your ROI: Since the rocks are crushing each other, the wear on the metallic liners is drastically reduced. This significantly lowers your Opex (Operating Expenditure) per ton of sand produced.

Concrete strength and workability depend heavily on the aggregate's shape.

Superior Cubical Shape:Traditional rod mills or cone crushers can produce elongated or flaky particles that increase the void space in concrete mixtures, requiring more expensive cement and water to fill.

VSI Advantage: The high-velocity impact of the VSI rounds off sharp edges, producing a highly cubical product. This improves the flowability of concrete and reduces cement consumption—a massive selling point for your downstream customers.

The Roller Crusher Machine VSI Series is not a one-trick pony. It offers dual functionality:

Sand Making: Converting 0-40mm limestone, basalt, or granite into 0-5mm sand.

Aggregate Shaping: Improving the shape of 10-20mm or 20-30mm gravel to meet highway asphalt standards.

We understand that maintenance downtime is lost revenue. Our VSI crushers are engineered with:

Hydraulic Lid Opening: Allows for quick access to the rotor for inspection without heavy lifting equipment.

Dual-Pump Oil Lubrication: Ensures the main bearing is always cool and lubricated, extending the machine's service life even under 24/7 operation.

The transition to Manufactured Sand is not a trend; it is the future of the industry. By integrating a VSI Crusher into your tertiary stage, you are not just buying a machine; you are securing your ability to supply premium materials in a market that demands nothing less.

Ready to produce high-margin M-Sand? Don't let poor particle shape devalue your product. Contact our engineers to get a custom VSI configuration and see how we can upgrade your production line today.