In the crushing industry, the price of a spare part is just the tip of the iceberg. The real cost lies in availability, longevity, and fit.

When a crusher stops, your revenue stops. Every hour of downtime can cost thousands of dollars in lost production. Is it really worth risking your entire operation to save a few dollars on a "compatible" jaw plate from a third-party foundry?

At BENO, we believe that genuine parts are not an expense; they are an investment in stability. Here is why switching to BENO OEM Parts protects your bottom line.

Two jaw plates may look identical, but their performance can be vastly different. The secret is in the metallurgy, whether for jaw crushers or components sourced from leading vertical shaft crusher suppliers.

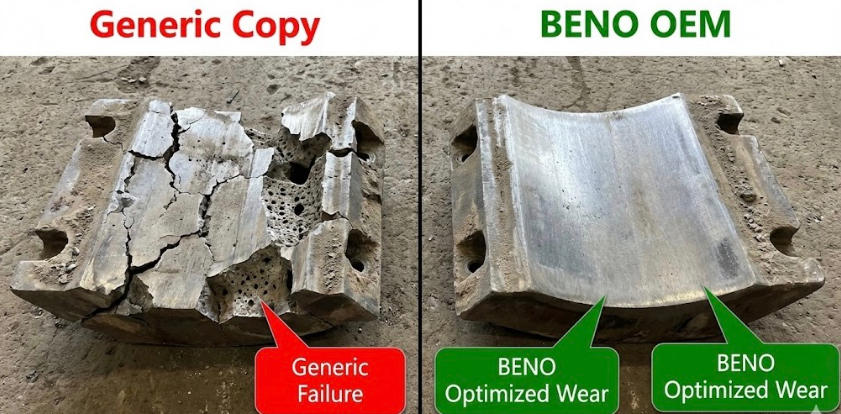

The BENO Standard: We use a proprietary high-manganese steel formula (Mn18Cr2 or higher) optimized for specific rock types. Our heat treatment process ensures the perfect balance between hardness (to resist wear) and toughness (to resist cracking under impact).

The Risk of Fakes: Generic parts often suffer from casting defects like air pockets or uneven cooling. This leads to premature wear or, worse, sudden catastrophic failure when hitting hard rock.

A crusher is a precision instrument. A gap of just a few millimeters in the liner seating can cause devastating vibrations.

Perfect Tolerance: BENO OEM parts are cast from the original engineering drawings. They fit perfectly every time.

The "Knock-on" Effect: Poorly fitting aftermarket parts can transmit shock loads to the crusher's main frame and bearings. Saving $500 on a liner could cost you $50,000 in main shaft repairs later.

When you buy a BENO part, you get a BENO engineer. Our service team doesn't just sell you steel; we help you optimize it.

Wear Analysis: We analyze your worn parts to understand wear patterns and root causes.

Optimization: Based on this data, we can recommend a different tooth profile or alloy to extend the lifespan of the next set by 20% or more.

Your BENO crusher was engineered for maximum performance. Keep it that way. Use only genuine BENO OEM parts to ensure maximum throughput, safety, and long-term asset value.

Need a replacement part fast? Don't wait for a breakdown.Check our Parts Inventory or upload your machine serial number here for an instant quote. We ship globally.