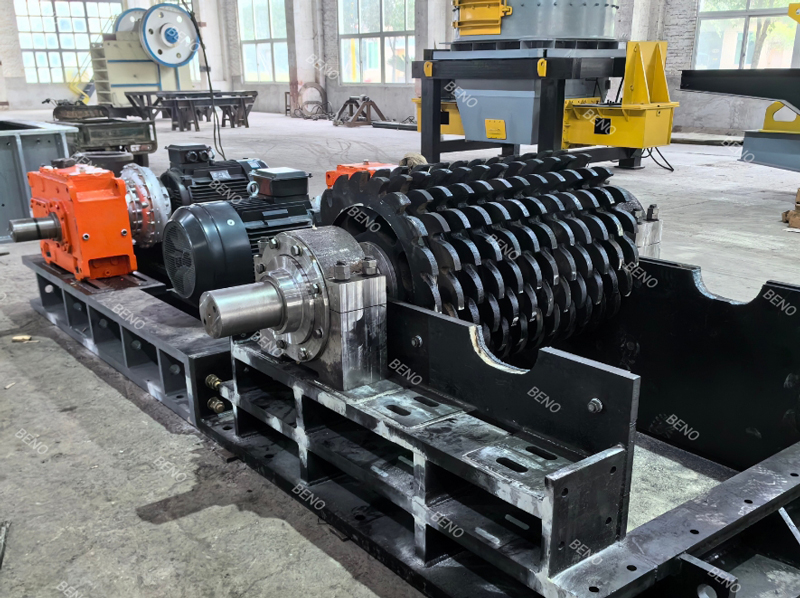

The structure of BENO Sizer Spindle must be rigid and stable enough to withstand the impact and vibration forces of the material.

BENO Sizer Spindle is driven to rotate by a motor, usually using mechanical transmission methods such as gear transmission or belt transmission.

The manufacture of BENO Sizer Spindles requires precision machining and assembly to ensure axis alignment and parallelism, as well as bearing seat accuracy.

Bearings are installed at both ends of BENO Sizer Spindle to support and position the rotation of BENO Sizer Spindle. Bearing selection and lubrication methods are crucial to the life and operating results of the spindle.

Materials are selected to meet strength and stiffness requirements.

The operation is stable and reliable.

The material is thick, and the replacement frequency is low.

BENO also provides patented sharp sizer gears for the improvement of the production capacity of the equipment. Welcome to the inquiry now!

Contact With Us:

E-mail: benoecepgroup@gmail.com

Have a Questions? Call Us:

Add:

No.10, 29/F, Building T2, Xiangnian Plaza, No.88 Jitai 5th Road, Gaoxin District, Chengdu, Sichuan

Please contact BENO for your mineral processing solutions!