In the competitive landscape of mining and infrastructure construction, operational efficiency is the primary driver of profitability. Traditional static crushing plants, while powerful, often incur high infrastructure costs and lack the flexibility required for dynamic project sites. For project managers and quarry operators aiming to minimize cost-per-ton and maximize uptime, the shift towards tracked mobility is undeniable. Enter the XC-400 Crawler Cone Mobile Crushing Station—a solution engineered to tackle the most demanding secondary and tertiary crushing applications with precision and agility.

The decision between a stationary plant and a mobile station often determines the project's bottom line. The primary challenge with static lines is the significant "hidden cost": concrete foundations, electrical installation, and the expensive logistics of hauling raw material to the crusher.

The XC-400 eliminates these bottlenecks. By bringing the crushing station directly to the extraction face, operators can:

· Reduce Material Transport Costs: Eliminate the need for heavy trucks to haul blasted rock long distances.

· Accelerate Site Setup: Go from transport to operation in a fraction of the time required for static plants.

· Enhance Site Safety: Fewer transport vehicles mean reduced traffic and lower accident risks on-site.

The XC-400 is not just about mobility; it is about bringing high-performance cone crushing technology to the tracks.

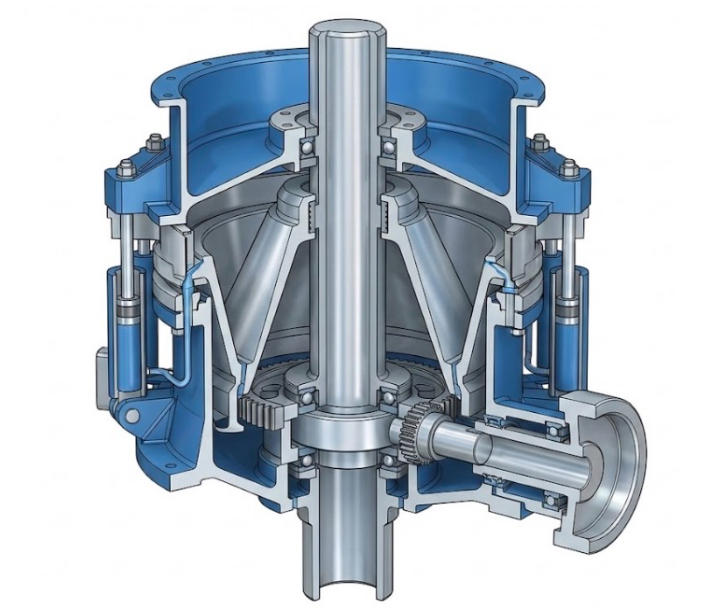

At the heart of the XC-400 lies a high-performance hydraulic cone crusher. Unlike standard crushers, this unit features an optimized cavity design and high crushing throw. This results in excellent inter-particle crushing, producing cubical aggregates with a high percentage of fines—crucial for meeting strict asphalt and concrete specifications.

The crawler chassis is designed for rugged terrains. Whether navigating a muddy quarry floor or a steep construction site, the XC-400 maintains stability. Its low ground pressure ensures it can operate in environments where wheeled mobile plants might struggle.

Modern mining demands data. The XC-400 comes equipped with an intelligent control system that monitors oil temperature, pressure, and crusher load in real-time. This predictive maintenance capability helps operators address potential issues before they lead to costly downtime.

Investing in the XC-400 is a strategic capital expenditure (CapEx) that lowers operational expenditure (OpEx).

Cost Factor | Traditional Static Plant | XC-400 Mobile Station | Benefit |

Civil Works | High (Concrete foundations) | Zero | Immediate Setup Savings |

Material Haulage | High (Trucks + Fuel + Labor) | Low (Crush at the face) | Significant Fuel Savings |

Resale Value | Low (Hard to relocate) | High | Liquid Asset |

The XC-400 excels in specific high-demand environments:

· Hard Rock Quarrying: Processing granite, basalt, and river pebbles where cubical shaping is mandatory.

· Road & Bridge Construction: Producing base materials on-site, reducing reliance on external suppliers.

· Mining Operations: Secondary crushing stages where high throughput and mobility are paramount.

The industry is moving away from rigid infrastructure towards agile, high-yield solutions. The XC-400 Crawler Cone Mobile Crushing Station represents the convergence of mobility and crushing power. It allows operators to adapt to changing site conditions without sacrificing production capacity.

To see how the XC-400 can be configured for your specific geology and capacity requirements, contact our technical engineering team for a customized simulation today.