In any aggregate or mining plant, the primary crusher is not just a machine; it is the gatekeeper of your entire production line. If the primary crusher fails, the conveyors stop, the secondary crushers sit idle, and your daily output targets are missed.

For operators dealing with hard, abrasive materials like granite, basalt, or river pebbles, selecting the right Jaw Crusher is the most critical decision in plant design, a choice that includes evaluating the offerings of reputable portable jaw crusher manufacturers for flexible and mobile solutions.

This guide analyzes why the PE/PEX Series Jaw Crusher remains the industry standard for primary crushing and how optimized design features can significantly lower your operational costs.

The primary stage faces the harshest conditions. It must accept large, irregular run-of-mine (ROM) stones and reduce them to a manageable size for secondary crushing.

Common issues with generic jaw crushers include:

· Uneven Wear: Poor motion characteristics lead to rapid wear on the jaw plates.

· Low Crushing Ratio: If the primary crusher doesn't reduce the size enough, it puts excessive load on the secondary crushers (like Cone Crushers), increasing overall energy consumption.

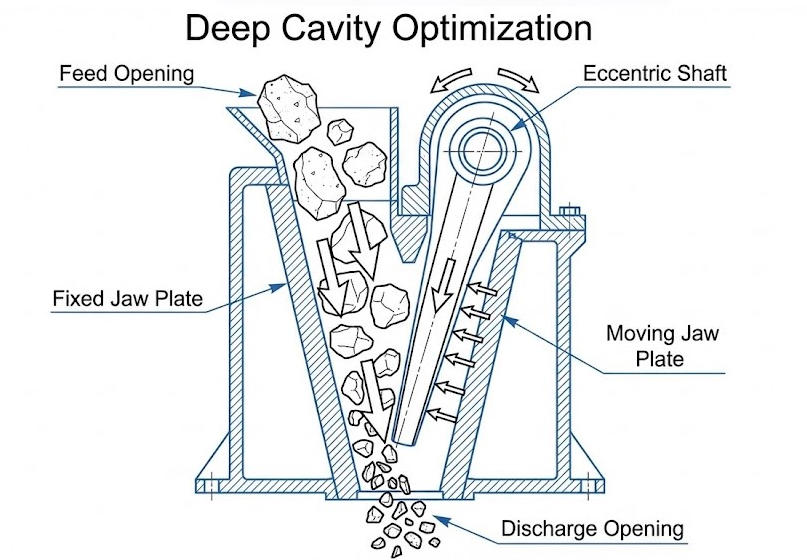

At Roller Crusher Machine, our Jaw Crushers are engineered with a distinct advantage: a Deep Cavity Optimization.

Unlike shallow-chamber crushers, a deep crushing cavity ensures:

· Improved Feeding: It accommodates larger feed sizes without bridging or blocking.

· Higher Crushing Ratio: The material stays in the chamber longer, undergoing more compression cycles. This results in a finer output size, which directly reduces the workload and wear on your secondary crushing equipment.

Industry Insight: An optimized crushing ratio in the primary stage can increase the lifespan of your secondary crusher's liners by up to 20%.

Operational stability comes down to metallurgy and mechanics.

The fixed and movable jaw plates are the most consumable parts of the machine. We utilize high-grade manganese steel alloys that work-harden under impact. This means the harder the rock you crush, the tougher the surface of the jaw plate becomes.

The toggle plate serves a dual purpose: it adjusts the discharge opening and acts as a safety fuse. If uncrushable material (like iron) enters the chamber, our engineered toggle plate is designed to disconnect immediately, protecting the expensive main shaft and bearings from catastrophic damage.

Time spent on maintenance is time lost in production. Our Jaw Crusher features a gasket-based discharge opening adjustment (or hydraulic assist options depending on the model). This allows operators to adjust the output size quickly and safely, without the need for cumbersome shims or prolonged downtime.

The simple, fly-wheel design ensures that the machine is easy to lubricate and inspect, requiring minimal training for onsite personnel.

A cheap crusher ends up being the most expensive one due to frequent breakdowns and parts replacement.

Whether you are setting up a new aggregate line or upgrading an existing quarry, the Jaw Crusher from Roller Crusher Machine offers the balance of brute force and engineering precision needed to handle the toughest ores.

Planning a new crushing line? Don't let the primary stage be your bottleneck. [Contact us today] for a free consultation on configuring the right Jaw Crusher model for your specific rock hardness and capacity requirements.