For mining project managers and plant engineers, material handling efficiency is directly tied to profitability. One of the most persistent challenges in primary and secondary crushing stages is dealing with wet, sticky, or elastoplastic materials (such as coal with high moisture content, clay, or soft shale).

Traditional jaw or cone crushers often fail in these scenarios, leading to blocking, frequent downtime, and skyrocketing maintenance costs. This is where the Sizer Crusher (also known as a Mineral Sizer or Twin-Tooth Roll Crusher) distinguishes itself as a game-changer.

In this technical guide, we explore how Sizer Crushers optimize your production line and why they are becoming the industry standard for specific crushing applications.

In many mining operations, particularly in coal preparation and metallurgy, the moisture content in raw materials can fluctuate significantly. Traditional crushing equipment relies on compression forces. When wet material enters a compression chamber, it compacts into a solid cake, causing blockage.

The result? Unplanned shutdowns to manually clear the chamber, creating safety risks and halting production. To maintain a competitive ROI (Return on Investment), operators need equipment designed specifically for these adverse conditions.

Unlike traditional crushers that rely purely on compression, the Sizer Crusher utilizes a unique combination of high-torque, low-speed technology.

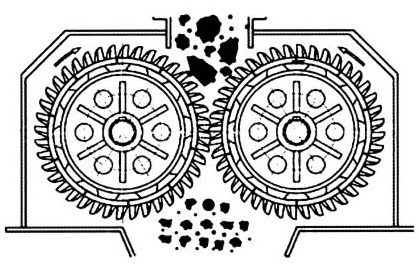

Shearing and Tensile Force: The twin-toothed rollers rotate inwardly. The teeth grip the material and subject it to tension and shear forces.

Specific Sizing: Since rocks are weaker in tension than in compression, the Sizer Crusher breaks the material along its natural grain.

Self-Cleaning Mechanism: The intermeshing teeth design ensures that any sticky material adhering to the roller is automatically scraped off by the opposing roller's teeth/cleaning bars.

Technical Note: This mechanism allows the Sizer Crusher to handle feed materials with high moisture content without clogging, ensuring continuous throughput.

Beyond handling difficult materials, integrating a Sizer Crusher from Roller Crusher Machine into your circuit offers strategic operational benefits:

Reduced Fines Generation (Better Product Quality)

Over-crushing is a major issue in coal and brittle mineral processing. Because the Sizer Crusher breaks material quickly and allows undersized particles to pass through the gap immediately, it produces a uniform product size with minimal fines (dust). This directly improves the yield of sellable product.

Compact Design and Low Profile

Space is often a premium in underground mines or mobile crushing stations. Sizer Crushers offer a high capacity-to-size ratio. Their low height makes them easy to retrofit into existing plants or install in mobile units.

Energy Efficiency and Low Opex

The direct drive system and the physics of tensile breaking require significantly less energy compared to crushing by compression. This translates to lower electricity bills per ton of crushed material.

While versatile, the Sizer Crusher is the preferred equipment for:

Coal Industry: Raw coal crushing (primary and secondary) where moisture is present.

Power Plants: Sizing coal for boilers to ensure combustion efficiency.

Cement & Quarrying: Crushing limestone, gypsum, and clay.

Selecting the right crusher is not just about purchasing machinery; it’s about investing in a solution that minimizes downtime and maximizes output quality. For operations dealing with sticky feed or requiring strict particle size control, the Sizer Crusher is the superior choice.

At Roller Crusher Machine, we specialize in engineering robust crushing solutions tailored to your specific mineralogy.

Is your current crushing equipment struggling with wet material? [Contact our engineering team today] to discuss your material analysis and get a customized Sizer Crusher proposal.